Getting hold of a piece of synth history, and a piece of my own history as well. And fixing it is just like everybody tells you it is.

Category Archives: Reparieren

In case your Canon TR8550 (etc.) printer does no longer connect to the WLAN

I’ll just put this on the Internet in case somebody else is searching for a solution to this problem which I couldn’t find anywhere, although it’s fairly easy:

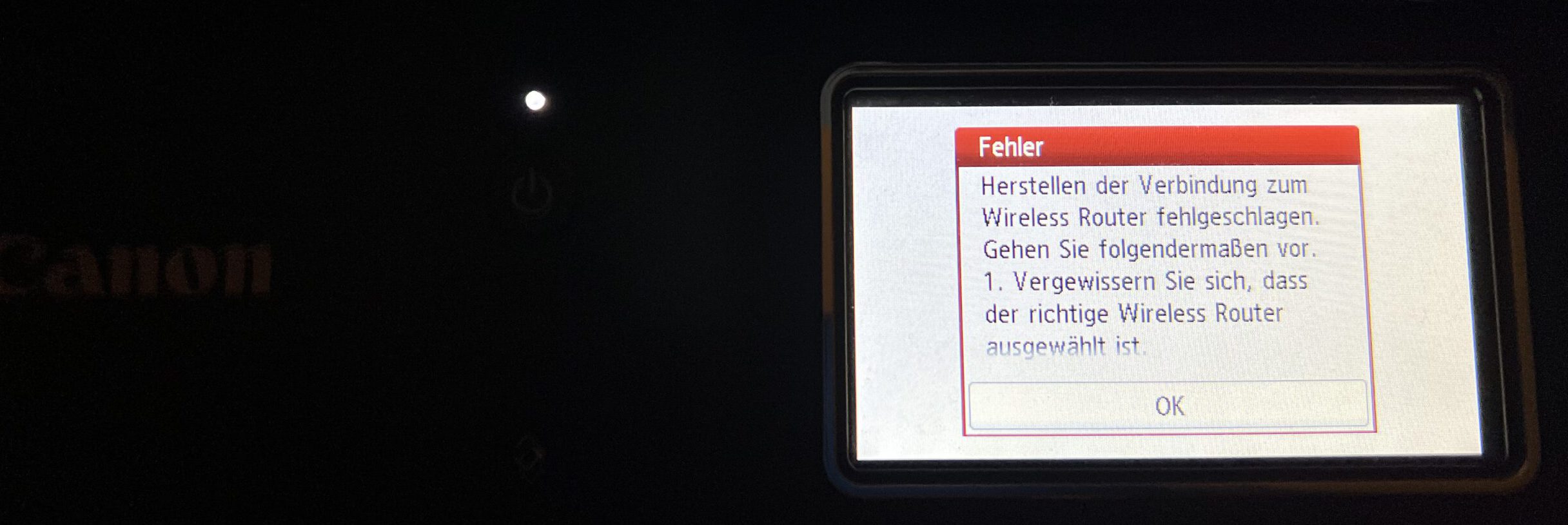

If your WLAN access point has activated WPA3 security along with the WPA2 standard, the Canon printer refuses to connect to the WLAN network and stops without asking for a password.

Canon did not help me very much: The interactive manual promises a solution that never comes. It offered a download page for software where I could not download anything. The name of the program that was supposed to fix the problem had changed – and guess what the software to fix the printer’s networking problem needs? Right – a network connection to the printer. USB does not work.

Changing or updating your router might disappear the Canon printer from the network

What had started this: I had to do some maintenance work in my home network; updating and resetting the OpenWRT firmware of my main WLAN router. And suddenly, the printer was gone. It refused any attempt at reconnection. It told me wireless encryption was off, but offered no option of reactivating it.

Strangely enough, I had the very same problem when trying to connect to my secondary AP, a Fritzbox managed by the ISP. So it couldn’t be the router update, then?

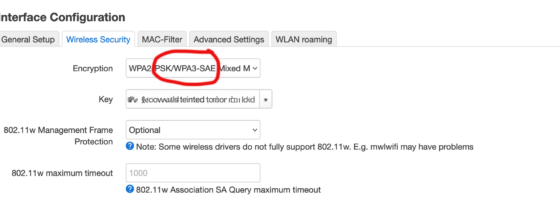

Well, yes, it could. I never noticed with the Fritzbox, but both routers now offer WPA3, a more modern and presumably better wireless security standard. (German Erklärartikel for AVM Fritzbox.) Which overwhelms the firmware of the four-year-old printer. Most recent update, of course.

So what you will have to do is to limit wireless security. Meh. Like, maybe, a firmware update would be nice?

Honorable Mention: My Sony-Playstation 3 has been getting updates for over 15 years now, and continues to do so. Which is really, really rare in home electronics.

Thermomix TM21 electronics: Speed knob maintenance

(I wasn’t willing to translate that myself; GPT-4 generated translation. German original here.)

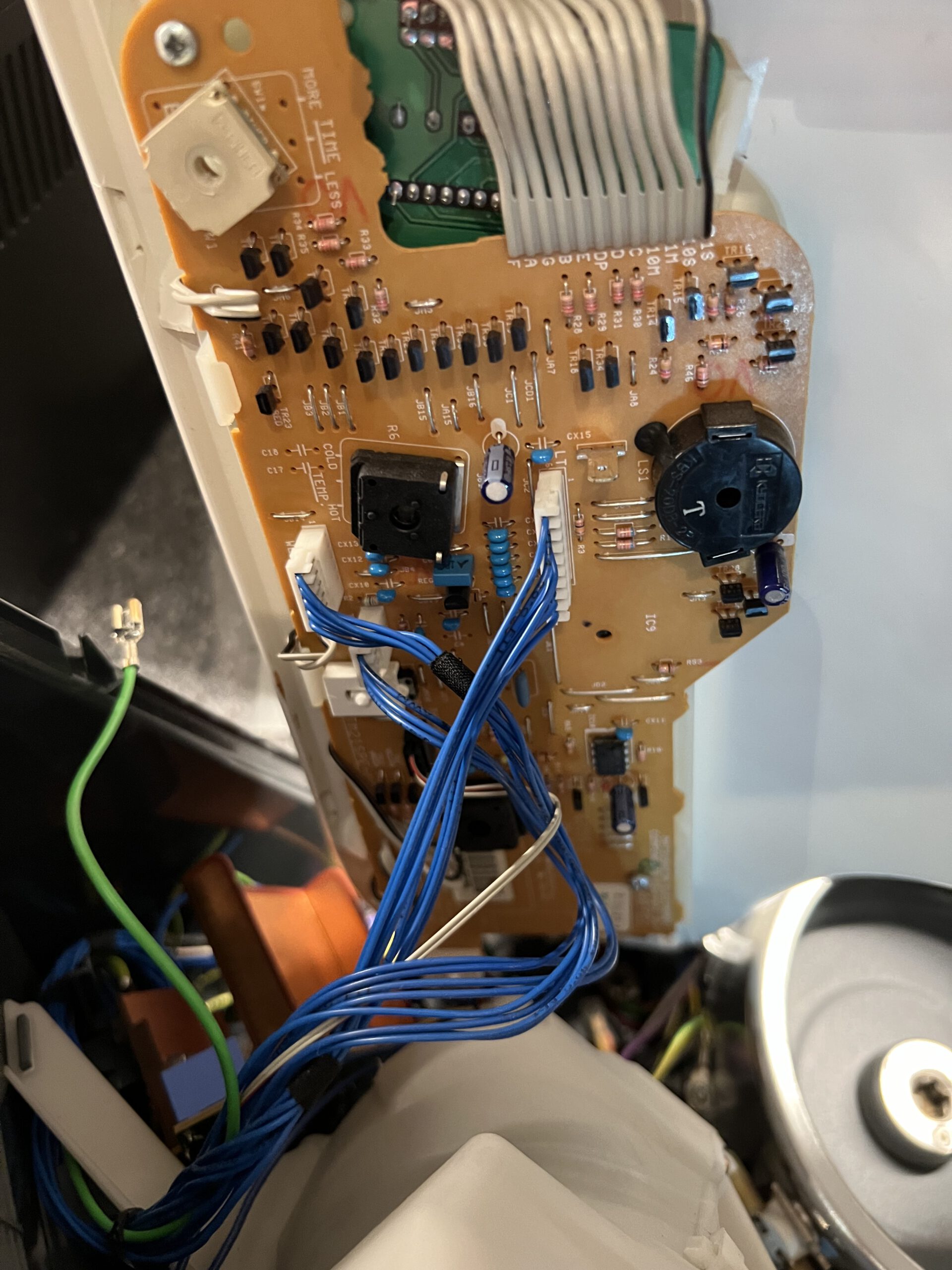

Unhooking and Folding Away the Upper Casing Shell

Next step is to unhook and fold away the upper casing shell. Disconnect the cables from the electronics – there are three white flat connectors with blue wires in different sizes, one black (with two grey cable cores), and the contact shoe of the green grounding wire. Once these are disconnected, you can remove the entire upper shell from the device.

Buggered those Push Buttons!

These can be tricky. That’s why it’s a good idea to watch a tutorial first.

Understanding the Push Buttons Mechanism

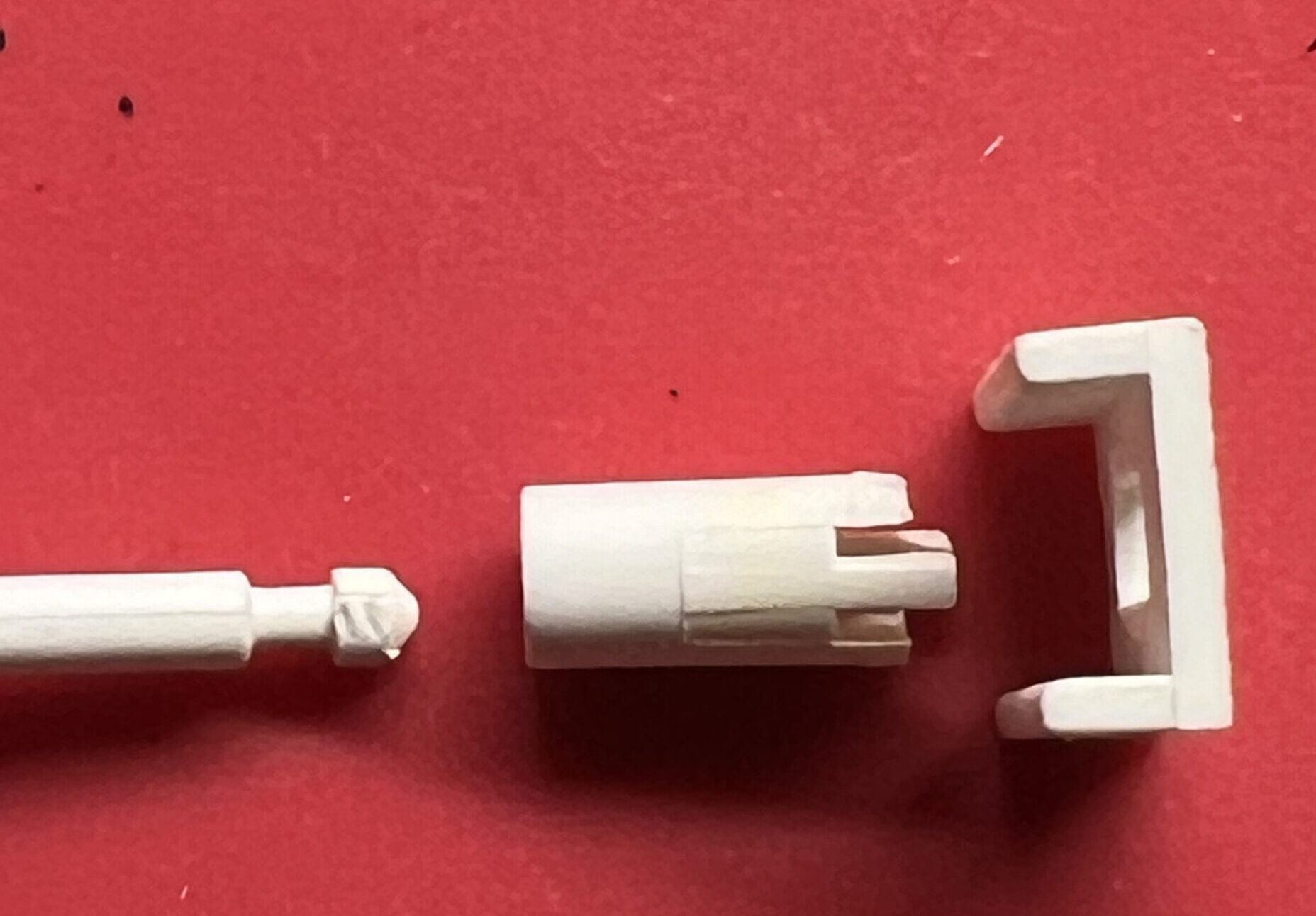

The push buttons are comprised of two main parts: the actual button, which protrudes from the front of the casing with a pin attached to it, and a counterpart that keeps the switch contact closed as long as no one presses the button. To remove the button, you need to detach the top part from the pin. That much is clear.

Unfortunately, the only solution I could think of was to use force, which led to me tearing off the rectangular plate on top. (This plate presses the switch.) It’s flanged to a tube where the pin goes, and at its upper end – visible through the slit below the plate – there are two small arms that hold the pin. You need to spread them apart using two small watchmaker’s screwdrivers, then you might be able to pull out the pin. Maybe.

Or, it might end up looking like this – the part in the middle and the one on the right are actually supposed to be connected; I ended up brutally tearing them apart.

I resorted to the reliable two-component adhesive. It worked after reassembling, and I hope it holds permanently, though I’m not very confident. If I can’t find replacement parts, maybe I’ll 3D print them, or else I might just permanently attach the plate to the pin.

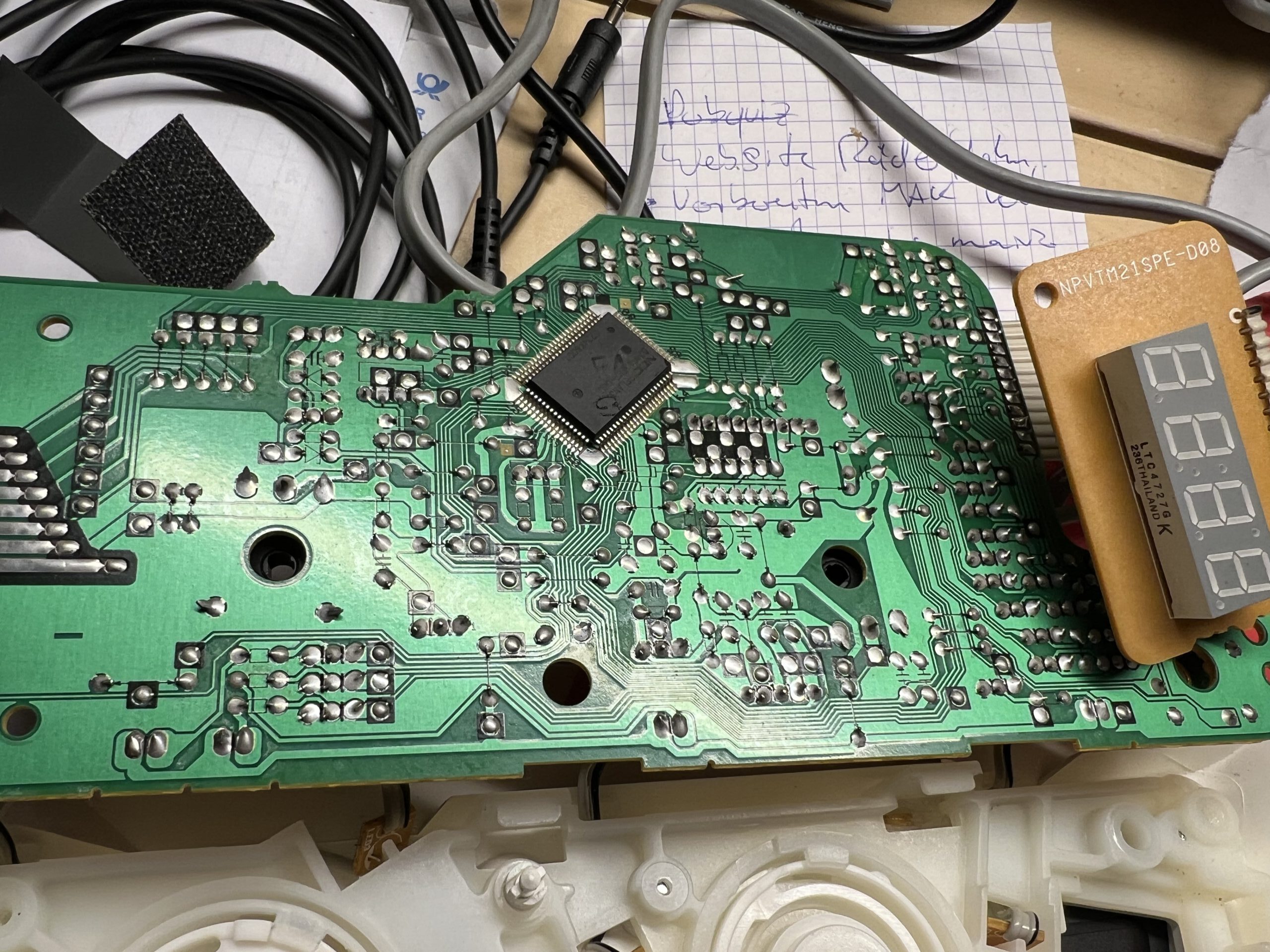

Next, unscrew the three screws from the circuit board and unhook the display, which is held in place by two plastic tabs. Then, remove the electronics.

The potentiometers are soldered at three contacts as usual and additionally held by two tabs that are inserted through the housing and bent over. Carefully unbend these, lift the three poles of the potentiometer, and remove it.

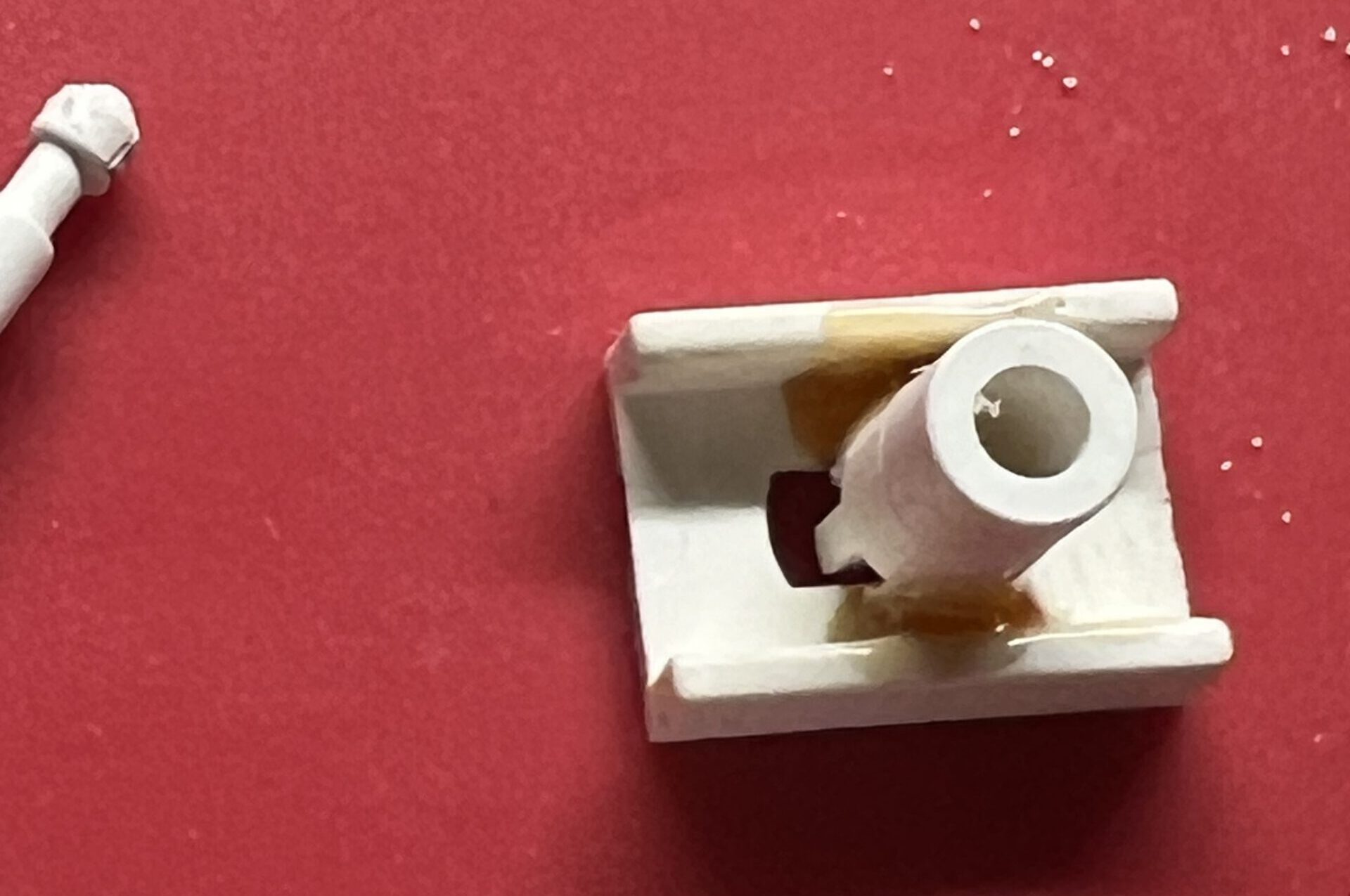

It’s a 22k potentiometer from Piher. I couldn’t find a replacement part quickly, so I decided to open it up. (Update: I’m trying with a Pipher PT15NH now; that’s the closest approximation I could find with that through-hole shaft. Piper datasheet here.)

The cover is pressed onto the housing from the bottom and riveted over four plastic pins; you have to cut these slightly with a scalpel, then the cover can be pried open.

With the potentiometer open, do what one does with open potentiometers – clean the wiper and track with isopropanol or mild alcohol, gently bend the wiper contacts back into shape, and – I am grinding my teeth while writing this – apply a little contact oil, if available. Absorb any excess oil, reassemble the potentiometer, solder it back in place, bend the tabs back, and it’s done.

Reassemble everything – and it works.

Sandwich toaster Krups FDK451 – how to dismount it to fix the holding clip

…and don’t listen to the random guy on Youtbe.

This seems to happen quite often:

It is no problem to get a replacement holding clip, and it’s cheap. The larger problem is to fit the replacement part, as you will have to take the top part of the housing apart for that.

Continue readingKaffee aus dem Jura

In which I am laying out the reasons for my conviction that the Jura brand coffee machine which I am trying to fix right now is a desaster. German only.

Bitte nicht nach einer Kalibrierung für das Pitchbend-Rad beim Blofeld suchen. (Macht er selber.)

One day, my trusty Blofeld started drifting out of tune – pretty unusual behaviour for a digital synth. Even if it was in tune first, the drifting started as soon as I touched the pitchbend wheel, so I suspected that this was the culprit.

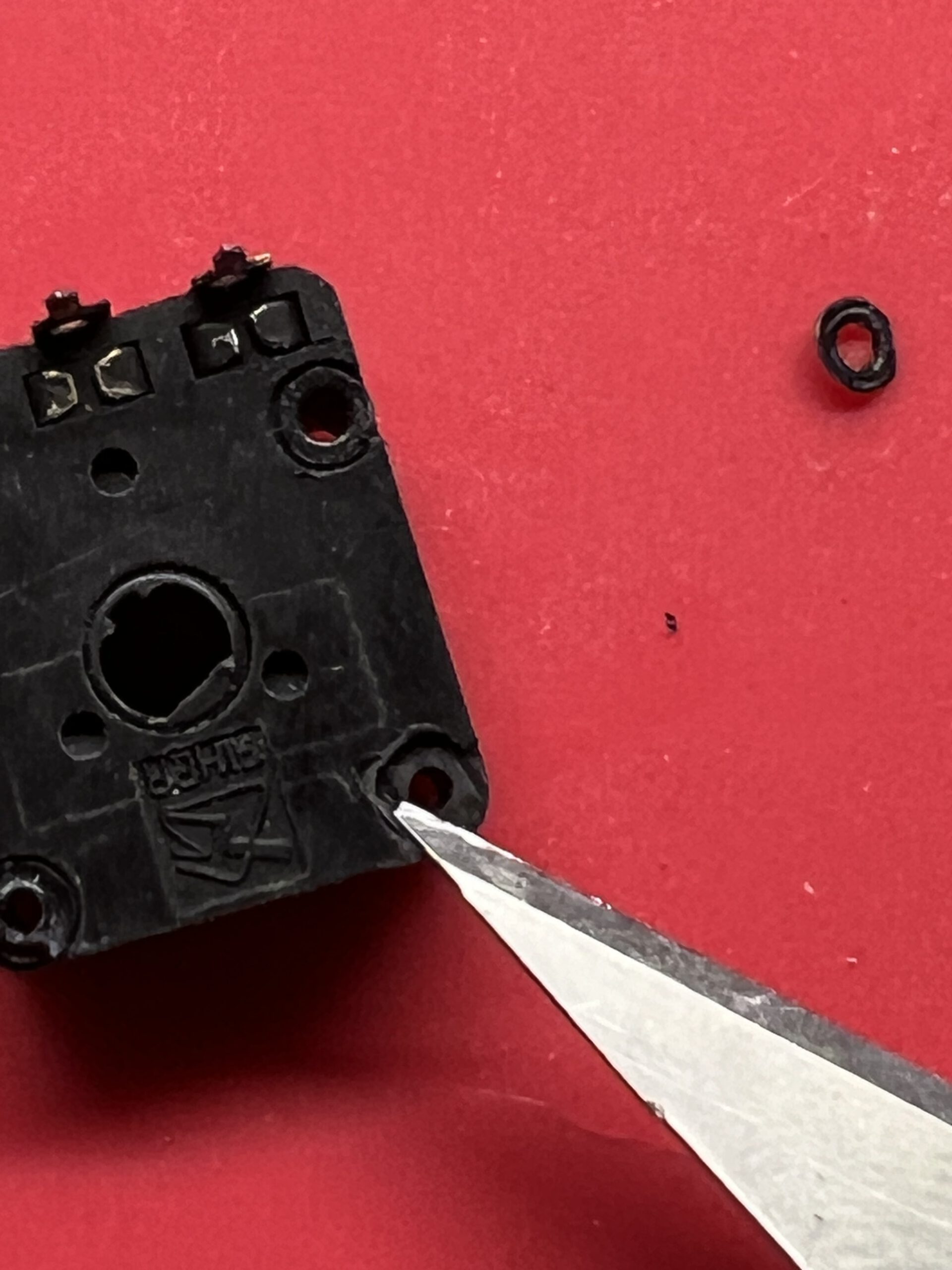

Opening the Blofeld (all 18 screws on the bottom – remember?), removing the wheelbox, and measuring the pitchbend pot confirmed that the potentiometer was indeed damaged – while an end-to-end-measurement showed 9k, the end-to-mid-resistance could be virtually anywhere, screaming “Mechanical Damage!” to me.

The potentiometer is 10k lin with a knurled 6.3mm shaft and an M10x0.75 mount. Waldorf seems to have used a Piher T-21Y type (datasheet). As I did not find something fitting in my parts boxes, I took it apart, cleaned it, adjusted the pickup spring, applied a bit of contact grease, refitted the pot and closed the Blofeld

And now for the good part…

Although I measured that the wheel now zeroed around the pot’s 5kOhm mark, it had most definitely shifted slightly, so I started looking for the calibration routine. There has to be a calibration routine, right?

But the good Blofeld seems to calibrate on power-up and on the first usage of the wheel – no calibration routine for the wheels needed. Phew!

Important note: Be careful to ensure that the Molex connector for the wheelbox sits correctly – when I pulled the plug, the plastic holder for the pins got pulled towards the edge of the PCB so when I reattached the plug, it did not sit correctly. Rule of thumb: If the plastic of the connector is visible from the top, you might want to push it back under the PCB.

Ich habe mit einem Uhrmacherschraubenzieher und Stocherei 340 Euro an Apple gespart

War unvorsichtig von mir, das iPad auf einer Platte abzulegen, auf der auch das Launchpad und ein Keyboard standen – beim Musikmachen muss man auf diesen Geräten nun einmal herumhämmern. Unmerklich setzte sich das iPad in Bewegung, und – klatsch.

Die gute Nachricht: Das Display hat überlebt. Auch das Gehäuse war nur wenig vermackt – das angeschlossene USB-Kabel zum Hub hatte den Sturz gedämpft. Und die Kamera hatte sowieso schon länger nicht mehr fokussiert. Dass es auch eine schlechte Nachricht gab, wurde mir erst zuhause klar, als ich das Ladekabel einstöpseln wollte und scheiterte: Der Lightning-nach-USB-Adapter, an dem das iPad hing, war in der iPad-Buchse abgerissen.

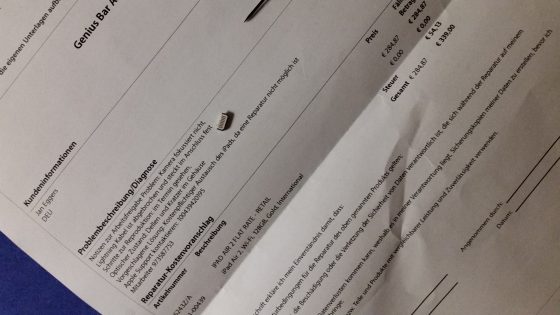

Na gut: da, wie gesagt, die Kamera ohnehin eine Macke hatte, habe ich einen Termin bei den Apple-Reparaturleuten vereinbart, im Apple-Sprech: an der Genius Bar. Den üblichen Zirkus mitgemacht: dumm rumgestanden, wieder weggeschickt worden, angestellt, nach 15 Minuten festgestellt, dass der Termin nicht stimmte, netterweise einen neuen bekommen, weggegangen, wiedergekommen, gewartet. Es ging ja nur um eine kurze Begutachtung.

Nach etwas Wartezeit kommt eine Endzwanzigerin auf mich zu. Sie duzt mich penetrant. Sie schaut sich das iPad nicht wirklich an – nimmt nur die Macken und Kratzer in ihr Protokoll auf. Das müsse wohl ausgetauscht werden, ich müsse nur noch unterschreiben.

Auf dem Reparaturauftrag steht ein Betrag von sage und schreibe 340 Euro.

Unterschreib endlich: Der Reparaturauftrag mit dem abgebrochenen Steckerstück, der das iPad “irreparabel” machen sollte

Der Preis schockiert mich. Ich habe noch sehr genau im Kopf, dass ein iPad Air 2 derzeit für etwa diesen Betrag gehandelt wird und mit 128GB Speicher nicht arg viel teurer ist. Ich lehne ab, den Auftrag zu erteilen. Damit hat die Endzwanzigerin offensichtlich nicht gerechnet, aber letztlich ist es ihr auch egal.

Für 340 Euro, denke ich, kann man eine Menge pfuschen. Eine Pinzette verbiegt, ebenso zwei Nadeln, mit denen ich versuche, das abgerissene Steckerstück herauszuziehen. Ein kurzer Blick zu iFixit verrät mir, dass die Buchse zwar nicht verlötet ist und sich deshalb gut austauschen lassen müsste – dass es aber ganz und gar kein Spaß ist, ein iPad Air 2 auseinanderzunehmen. (iPad-Gehäuse erhitzen, Kleber lösen und so.) Also stochere ich auf gut Glück weiter – und schaffe es schließlich nach einer guten halben Stunde mit einem winzigen Uhrmacherschraubenzieher, das Bruchstück herauszuhebeln. iPad ans Ladekabel – läuft. Glück gehabt.

Die Moral? Nicht die übliche Geschichte von den bösen, unfähigen Computerladenstudis. Die waren zumindest tendenziell sehr hilfsbereit, und sie haben halt ihre Regeln. Trotzdem bin ich froh, mich dem Apple-Imperium nicht unterworfen und nur mit meinem Werkzeug einen kleinen Sieg erkämpft zu haben: I’m not a number, I’m a free nerd!

Und die Geschichte meiner Hassliebe zu Apple ist um eine Episode reicher.