In which I have to admit that I have been wrong: the encoders in my Waldorf Blofeld synth do need a special lubricant; by cleaning all the grease from them I might have done more harm than good.

About a year ago, I had to take my Blofeld apart to fix its jumpy encoders. My solution at that time was to degrease them with a bit of ethylene alcohol as I found the contacts to be overly greasy, assuming that some lubricant had seeped onto the contact lanes, degrading the contact, so by cleaning the excessive lubricant away you’d be fine. And as the encoders really worked well after my cleaning, everything seemed to be fine.

Some time after posting about the matter, I got an e-mail from Achim, the guy behind stromeko.net – you may know the site for its wealth of Waldorf synth information and Blofeld samples/soundsets. He warned me that I might actually be killing the encoders, as they were most likely of a “self-lubricating” type, i.e. with a special, contact-enhancing grease. I had never heard of contact grease, so I asked my father – an electronics engineer with over 40 years of experience – and neither had he. (Ironically, he used to manufacture encoders, although high-resolution optical encoders – no contact problems there.) On the other hand, Achim sounded well-informed and well-meaning, and you should never disregard somebody whose e-mail footer makes mention of owning a Waldorf Wave. So I wrote back, and promised to check up on the issue.

And forgot about it.

Some months later, I remembered, researched that there is indeeed something called contact oil, and resolved to open up my Blo again. Unfortunately, this took until yesterday, but at least that year of using the Blofeld encoders – not really heavy usage, but regularly – gave me the opportunity to verify that Achim is actually right.

Ungreased encoder shows signs of abrasion

After a year, the encoders had started acting up occasionally again, and when a screw turned loose inside the Blofeld and started making a racket, the time for opening it up again has finally come. So I was curious what the encoders would look like after using them ungreased, and this is what I found:

As you can see, the contact lane shows clear signs of abrasion and wear by the ungreased pickup on the rotor.

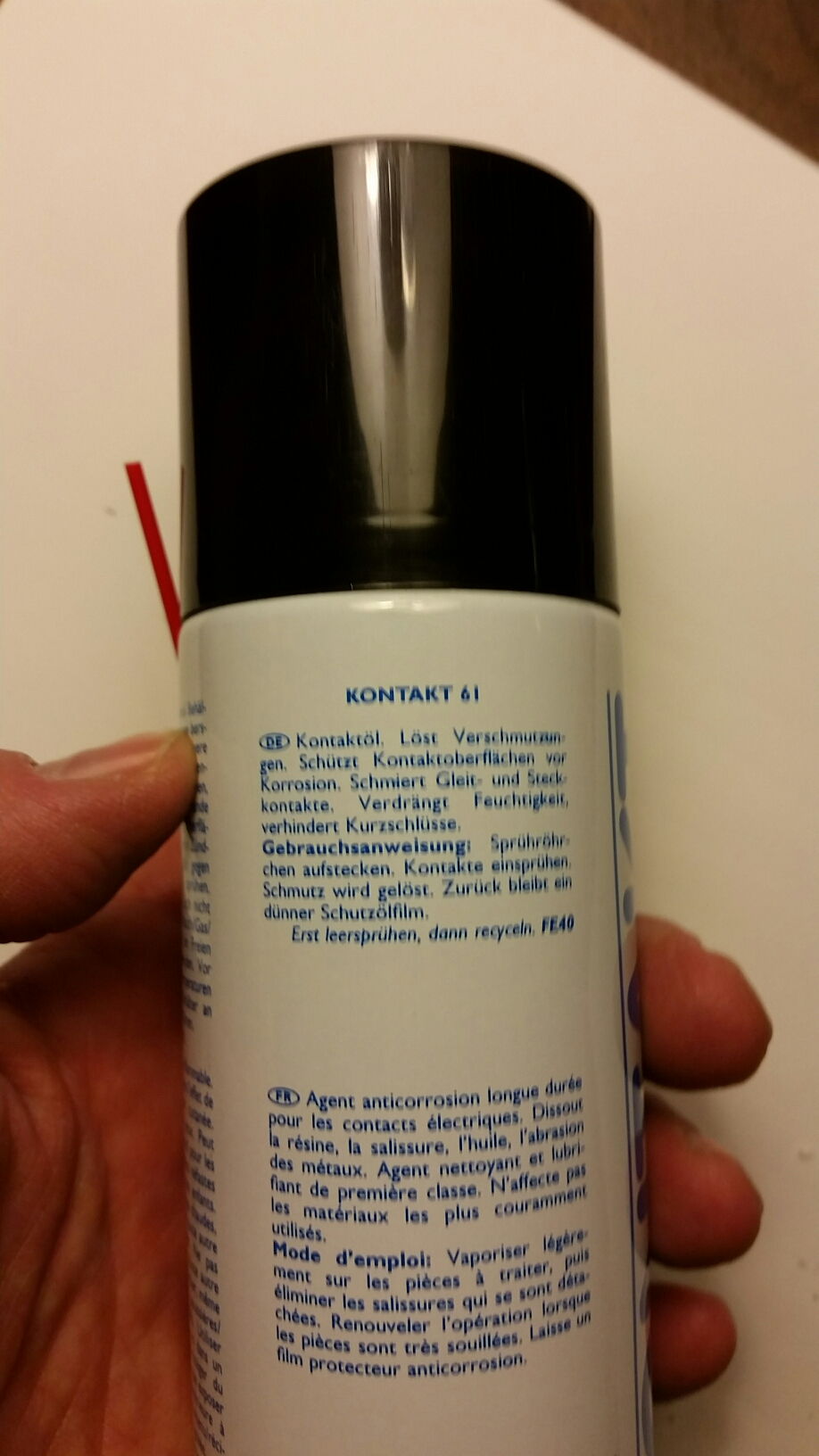

I cleaned the contacts again with alcohol to remove residuals, and applied Kontakt-61 contact oil. (I am generally a bit suspicious towards Kontakt spray, for reasons explained here, but this is a different product.)

Text on can says: “Contact oil. Dissolves dirt. Protects contact surfaces from corrosion. Lubricates pickup and plug contacts.”

So I owe Achim – and everybody who has read my first encoder post – a heart-felt public apology. I should have added Achim’s information much, much earlier. Well, I wanted to check first, but I should have done that earlier as well.

Well: sorry – and don’t use the encoders without a contact lubricant, as this might lead to premature failure due to wear.

Verwandte Artikel:

- Fixing a Waldorf Blofeld’s jumpy encoders (Sunday, 24. January 2016; Schlagworte: auseinandernehmen, dismount, DIY, Drehknöpfe, fix encoders, Synthesizer, Waldorf Blofeld)

- Fixing a Korg Polysix. A Polysix! (Saturday, 24. August 2024; Schlagworte: analog, Repair, Reparatur, Retro, Synthesizer, KLM-367, Korg Polysix)

- An Unreachable Quantum of Waldorf (Friday, 7. April 2017; Schlagworte: Musikmesse, Studiologic Sledge, Waldorf Blofeld, Waldorf Nave, Waldorf Quantum)

Pingback: Bitte nicht nach einer Kalibrierung für das Pitchbend-Rad beim Blofeld suchen. (Macht er selber.) - untergeekuntergeek

Thanks bro. Appreciated.

Pingback: Thermomix TM21 electronics: Speed knob maintenance - untergeekuntergeek