03-2020: Two important updates: There is a much simpler way to reset the memory in the Matrix – just hold the ENTER key while switching it on. You may have to repeat that a couple of times to get a stuck Matrix unstuck. And if you consider changing the battery yourself, you can find a step-by-step description with video here.

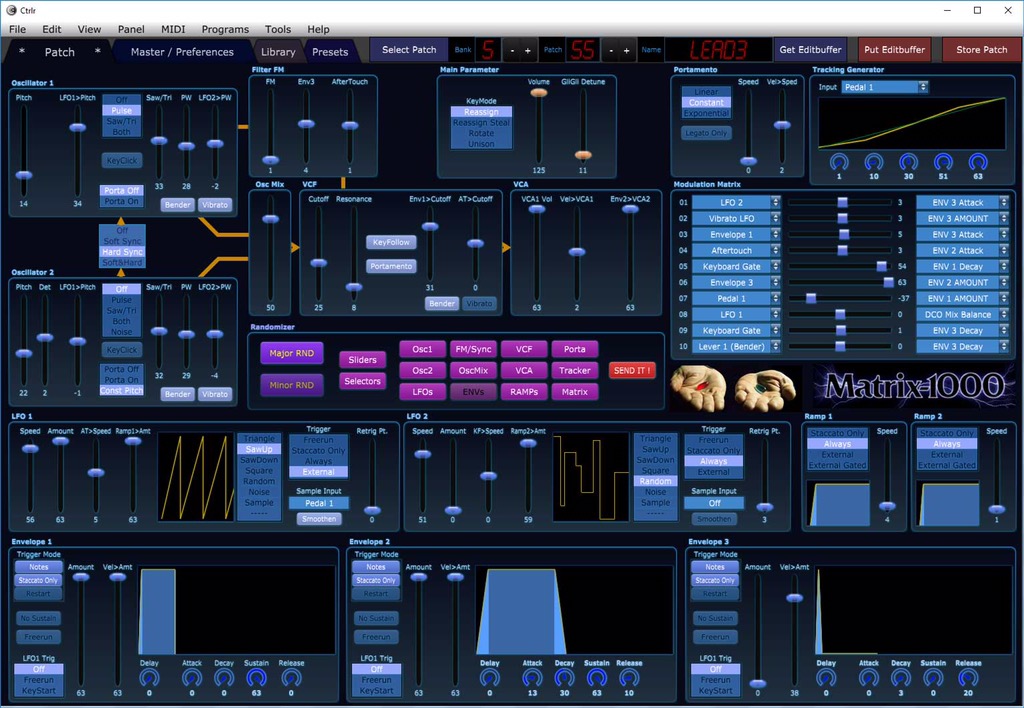

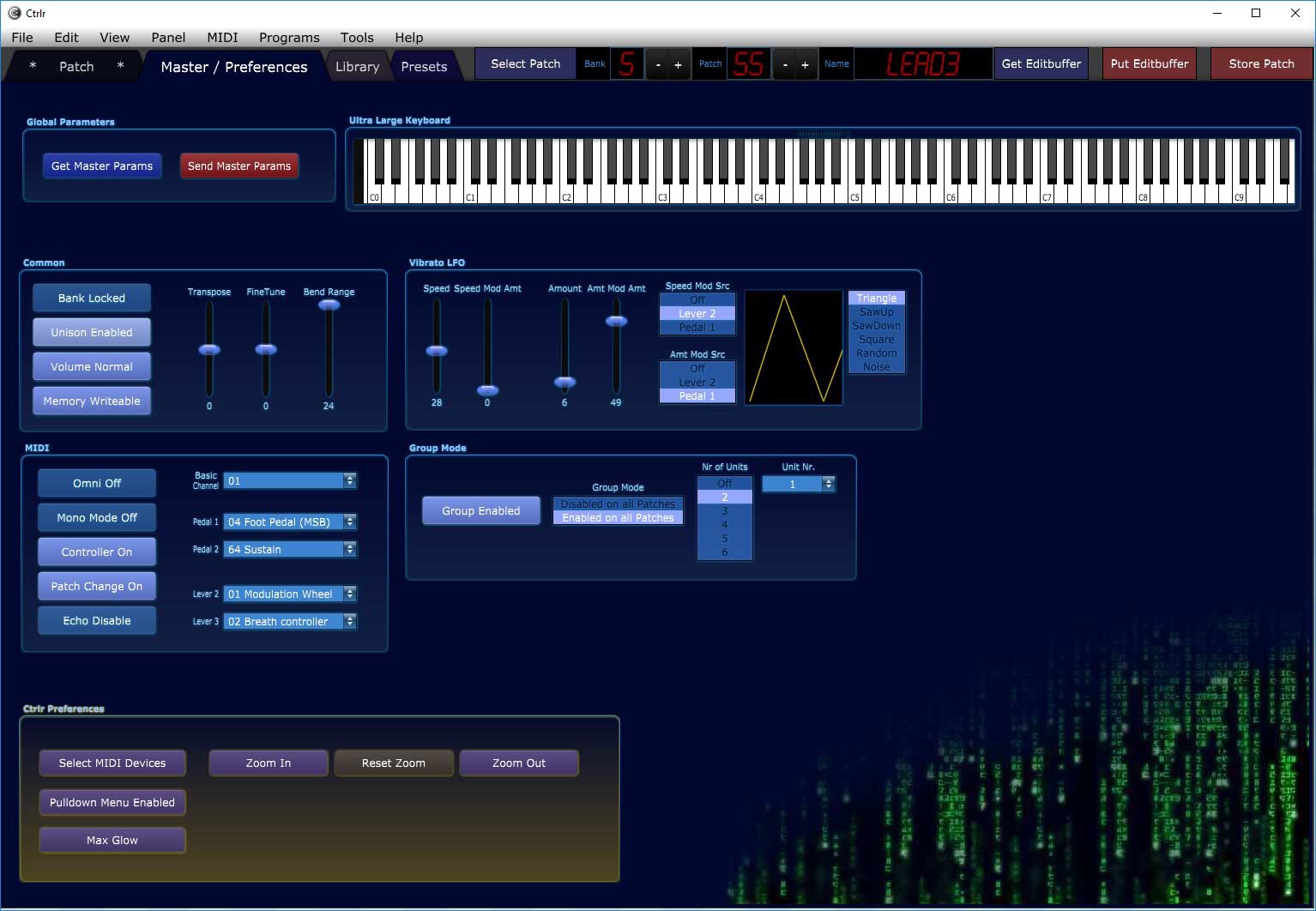

Happy days! Bob Grieb just sent the newest iteration of his brilliant firmware rewrite for the Oberheim Matrix-1000 for testing – a firmware that breathes new life into the old 8-bit hardware by optimising critical routines for a couple of crucial parameters. Smooth real-time control, very musical; in my opinion, even better than GliGli’s great v1.16 hack – I’ve described the differences in this Gearslutz post – and, in the last couple of iterations, displaying the value of edited parameters.

(I used Modstep as a drum machine/sequencer on the iPad, and my Matrix-1000 control panel for TB Midi Stuff – other than the new iPad editor, it does produce smooth parameter sweeps.)

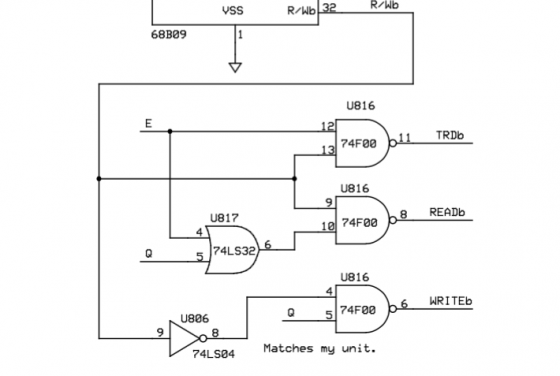

Well, to change the firmware, you have to open the Matrix and exchange the firmware EPROM for a new one, and doing that, I’ve noticed that this machine was still equipped with its original battery. By lucky chance, I am the proud owner of two Matrixes, and the battery in this one has been doing fine – what kind of super battery did they use in these days, has been in service ever since 1989, and still producing fine 3.0 Volts of power – but I decided to exchange it anyway for a new CR-2032.

As you might know, the battery in the Matrix-1000 is soldered in with most machines, as it was customary with most synths from these days. I guess they never thought that they were building for the anoraks of the future. No problem, I came across battery holders with the same 20.5mm raster used in the Matrix – so no need for drilling, just a simple solder-and-replace job. While soldering, I bridged the backup battery voltage with an external power supply, and I even thought of desoldering the GND terminal first – the rationale behind this being that soldering pens are earthed, so by soldering the positive terminal first you might short out the battery. (Actually bollocks, but I did it anyway.) So I saved my precious memory settings while soldering in the battery holder.

Only to slide in the new battery the wrong way round.

You might not have realised – well, I never do – but the pad connector of a CR2032 is actually the GND terminal, and the housing is Vcc. And is labeled with a clearly visible „+“ sign. Well, I put the battery in the wrong way round anyway, thereby effectively losing all my patch and memory settings.

The battery in its new holder, now in the correct position: the plus terminal facing upwards

This is, of course, no big deal. I keep moving sound banks between my two Matrixes anyway, so I have pretty recent Sysex backups. Unfortunately, the unbuffered RAM chip lost just enough memory to put the machine into an undefined state – it would no longer boot beyond the init routine displaying the firmware version.

So: How do you factory-reset a Matrix-1000 synth?

I ran into this problem before when I equipped my other Matrix with a new CPU – as you can imagine, this gave me some really bad moments. But factory-resetting an M-1000 is simple:

- Switch off the the M-1000, disconnect it from mains, open it.

- Disconnect the battery. Leave it disconnected.

- Switch the M-1000 on, draining its buffer capacitors. Leave it for a couple of seconds – the completely powerless RAM should be all FF’s now.

- Connect the M-1000 to mains, and switch it on. It should start now.

- Do a calibration run, just to be sure. (Navigate to Ext. Funct., select 7, Enter, select 2, Enter.)

- Reconnect the battery.

Done. Now you may switch off the Matrix, or supply it with fresh patch data.

In case you may have wondered, there is a very simple and effective way to disconnect/reconnect the battery in a running machine: push a strip of paper between the battery and the battery holder’s terminal. Remove it to reconnect.

In case you may have wondered, there is a very simple and effective way to disconnect/reconnect the battery in a running machine: push a strip of paper between the battery and the battery holder’s terminal. Remove it to reconnect.